The OK™ mill the most reliable and efficient mill for ...

Jun 07, 2018· The OK mill has been FL''s standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding.

WhatsApp)

WhatsApp)

Jun 07, 2018· The OK mill has been FL''s standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding.

the grinding process remains a challenging issue, due to the elevated degree of uncertainties, process nonlinearity and frequent change of the set points and the respective model parameters during operation. For productivity and quality reasons, grinding is mostly performed in closed circuits: The ball cement mill (CM) is fed with raw materials.

The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well as a coal mill with an output. Cement Industry Loesche. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low ...

It''s a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, ore dressing of ferrous metal and nonferrous metal, etc. Do your know how does the raw mill work in the cement plant? This paper mainly introduces the raw mill in cement plant.

controller to be achieved, able to attenuate the disturbances affecting the raw meal quality. KeyWords: Dynamics, Raw meal, Quality, Mill, Grinding, Model, Uncertainty . 1 Introduction . The main factor primarily affecting the cement quality is the variability of the clinker activity [1] which depends on the conditions of the clinker

Raw Grinding Mill Cement Industry Pdf. Cement industry is a kiln assigned a mill, get the highest returns on investment e graduation design on the topic of 5000 t d coal production line of raw material grinding .

That is why ABB has developed OptimizeIT Raw Mix Preparation (RMP): to offer raw mix quality assurance to the leaders of the cement industry. Optimize Raw Mix Preparation (RMP) depicts a comprehensive set of software solutions that cover all stages of the raw mix blending, from the quarry to its grinding, making sure that your quality

Vertical Roller Mills (VRMs) have been the standard option for raw materials grinding in the cement industry for several decades. FL has supplied the global cement industry with leading VRM designs for all applications since they were first brought to market. The OK™ mill has been FL''s standard cement VRM since 1993.

Atmaca and Kanoglu (2012) performed the first and second law analysis of a raw mill and certain measures are implemented in an existing raw mill in a cement factory in order to reduce the amount ...

Cement Industry in Your State; Apparent Use. State Market US Summary (13 Categories, 1 Year) ... Mill Grinding Course. PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course.

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill''s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application.

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials.

fineness of grinding with small energy consumption). 1. Generalities Different industries are using for grinding raw material and final products, exclusively rotary mills. For instance, in the cement industry, the raw used to produce cement clinker as well as the cement, is obtained by grinding in rotary mills. These mills consist of a ...

A raw mill is the equipment used to grind raw materials into "raw mix" during the manufacture of cement. Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissions. Process of raw mill in grinding of raw material and silo storage 1. Transporting crushed raw material to raw mill

Dec 01, 2017· 2) This raw meal is passed through the cement kiln at very high temperatures to produce clinker. 3) The cement mill grinds the clinkers to an appropriate heat to produce cement. Each step is critical but the final step is where the magic happens. Grinding to perfection. In the final step, the cement mill grinds the clinkers using horizontal ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

The Cement Industry typically produces Portland cement – ... Raw material grinding In the raw mill, the material chunks are ground finer to allow highquality blending. In this phase mainly vertical mills are used which grind the material through pressure exerted by rollers.

The proven energysaving grinding system. One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blast furnace slag.

grinding with a raw coal rate of approx. 12 t/h. 1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material. 1937 400 Loesche mills have already been sold for coal, phosphate and cement raw material. 1939 The largest Loesche mill at this time is an LM 16 with two steel springloaded rollers, a grinding track

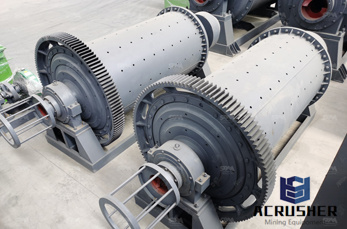

The segmentation of grinding and milling systems. Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and ...

Grinding Mills – Common Types. Previous Next. Metallurgical Content ... whilst in Fig. is shown a tube mill used in the cement industry the tube having a diameter of about 8 ft and length of about 45 ft. ... The raw material is fed in through a hollow trunnion at the entrance end of the mill and during grinding traverses the ball charge ...

Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground. As our solutions are designed to suit the customers'' requirements, we can guarantee that our mills work efficiently without any trouble.

AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING GREENHOUSE GAS EMISSIONS FROM THE PORTLAND CEMENT INDUSTRY . ... material is separated in a classifier that is recirculated and returned to the mill for additional grinding to ensure a uniform surface area of the final product. (Coito et al., 2005, and others.)

The raw mix is fed into a circular storage unit called a raw mix storage. Then, the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin for grinding. The other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron ore.

WhatsApp)

WhatsApp)